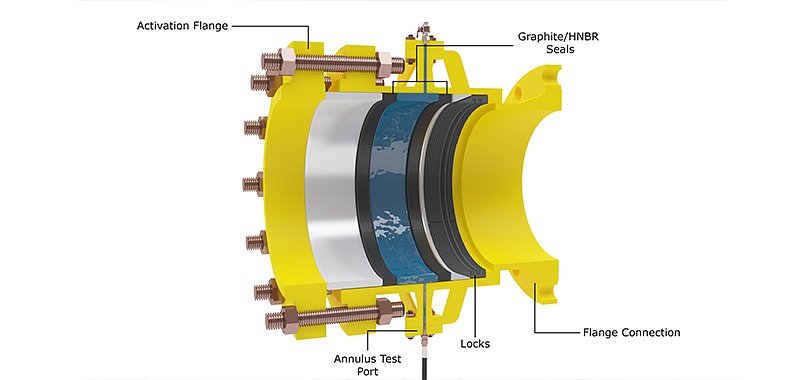

SIU custom designs, manufactures, services and repairs fluid film babbitt bearings and seals to keep large rotating equipment operating more efficiently and reliably over an extended life.

BABBITT REPAIR

A typical workflow includes the following

- Engineering trouble-shooting and analysis, repair and service, and manufacturing babbitt bearings for turbine and generators operating in nuclear power stations in North America, Western and Eastern Europe, Korea and South America;

- Turnkey custom-designed and manufactured large vertical guide and thrust bearings to solve problems in older existing machinery and new equipment at hydroelectric plants in North America;

- Our proprietary Fluid Pivot® technology for tilting pad radial babbitt bearings for high speed lightly loaded rotating machinery or, in larger sizes and in the “JS” configuration, as an ideal solution for a steady rest bearing or any application requiring superior bearing dynamic alignment;

- Providing manufacturing and repair services to the U.S. Navy and its major subcontractors since World War II, for nuclear aircraft carriers and submarines, frigates, destroyers and the Navy’s newest class: the Littoral Combat Ships (The Freedom variant)

- Qualified by the marine divisions of GE and Westinghouse Electric in 1956.

Our engineering expertise includes

-

Due to our longevity and license relationships over the years with OEMs of power turbines and generators, in addition to our extensive experience with General Electric marine and power generation bearings, we have more experience with anyone in the industry in North America repairing and servicing bearings designed by:

• Westinghouse Electric • ABB • BBC • Siemens • Alstom

Related Services

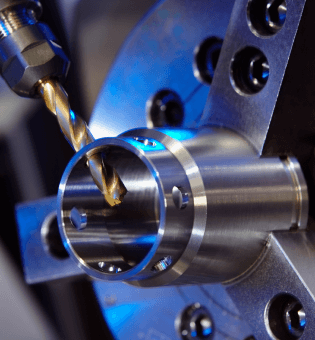

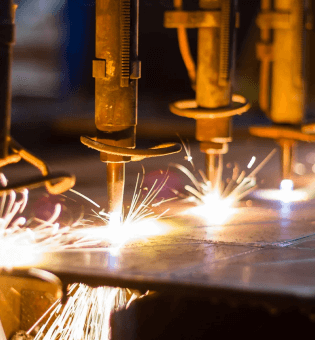

Premier supplier of precision metal parts and assemblies, specializing in stampings, castings, and precision machining. With the mechanical manufacturing facilities and expertise to create our own dies for castings and stampings, we carefully control all facets of the production environment. Our state-of-the-art machines punch, weld, press, shear, and cut to form just about any precision metal […]

We stock and source a wide range of Mechanical and Electrical spare parts for most makes and models of wrapper, all are high quality OEM specification and come with our full technical support.

If parts are obsolete, or lead times are just too long, we will source a suitable equivalent with the shortest available delivery to get you up and running ASAP.

Contact us to discuss your needs.

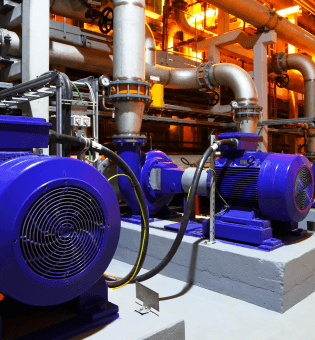

24/7 MARINE DIESEL ENGINE SERVICES The Coliemakhi facility includes a modern machine shop incorporating a medium and high speed engine and water jet propulsion divisions, fully equipped with the latest in repair and test equipment. Coliemakhi is an authorized service center for many of the world’s major diesel engine and propulsion system manufacturers. Motor-Services Hugo […]

SIU have the necessary technically qualified manpower, readily available with extensive equipment resources to provide a quality, cost effective range of in-situ service that achieve desired results within acceptably short time frames.

SIU have the necessary technically qualified manpower, readily available with extensive equipment resources to provide a quality, cost effective range of in-situ service that achieve desired results within acceptably short time frames.

SIU have the necessary technically qualified manpower, readily available with extensive equipment resources to provide a quality, cost effective range of in-situ service that achieve desired results within acceptably short time frames.

SIU have the necessary technically qualified manpower, readily available with extensive equipment resources to provide a quality, cost effective range of in-situ service that achieve desired results within acceptably short time frames.