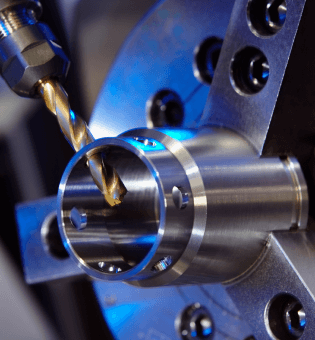

Mactech Europe Ltd is able to cater for all types of on-site milling requirement.

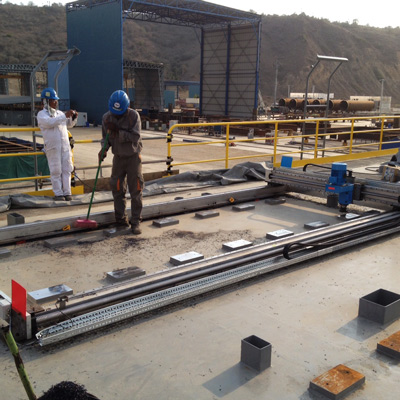

We have a comprehensive range of portable milling equipment, with the capability of milling large areas in a single set up.

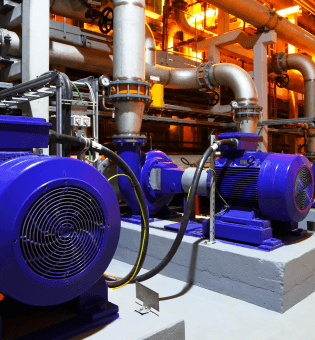

Our multi axis portable milling machines have been designed specifically for milling pump and motor bedplates, heat exchanger partition plates & grooves, external and internal keyways, ‘T’ slots, as well as square/rectangular flanges.

With our modular equipment design we can make use of a combination of heads, slides, beams and rails, configured to provide a diverse range of precision milling services.

Machines are typically fixed to the work piece by utilising existing bolt holes, however, if there are no existing fixing points present we will drill and tap to suit, or tack weld our equipment into position.